HEIGHT GAUGE – G50

INSTRUMENT FOR THE TAPPING MACHINE TO MEASURE THE HAMMERS FALL HEIGHT

The height gauge G50, produced by Sources Line is a specific gauge that makes it possible to verify the height fall of the Tapping Machine’s hammers before the beginning of a test.

The measure detected by the G50 gauge is useful to ascertain that the Tapping Machine follows the parameters established by the NEW REGULATIONS 16283-2, that concerns also the hammers height fall.

HOW THE G50 IS FABRICATED: all the parts that compose the gauge are made with lathes and milling machines with numeric control: the handle, the basis, the caster and the mobile head.

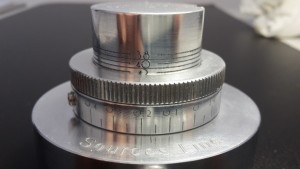

A nonio is engraved on the spiked caster and enumerated notches are engraved on the mobile head.

G50 is completely made of aluminum that, before the assembly, is accurately polished with specific grinders.

During the assembly, the caster and the mobile head are polished to be able to spin and to flow freely.

After the assembly process the height is calibrated bringing the nonio to zero, comparing it to a certificated gauge.

TECHNICAL SCHEDULE

| MATERIAL | Aluminum | HEAD DIAMETER | 28,0 mm |

| WEIGHT | 200 gr | HEAD HEIGHT (MIN.) | 29,0 mm |

| BASIS DIAMETER | 60,0 mm | HEAD HEIGHT (MAX.) | 44,0 mm |

| BASIS THICKNESS | 16,0 mm | MEASURE RELIABILITY | Verified with certificated gauge |

| NONIO’S CASTER DIAMETER | 40,0 mm | HANDLE LENGHT | 120,0 mm |

| NONIO’S CASTER THICKNESS | 12,0 mm | HANDLE DIAMETER | 10,0 mm |

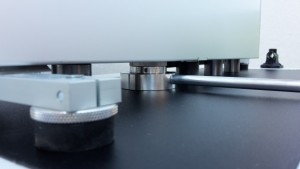

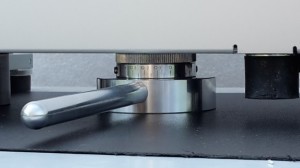

HOW TO USE IT: G50 is an easy instrument to use; to rise and rotate counter-clockwise and then clockwise the spiked caster (pic. 1/2). Lift the head at the nominal height of 40 mm (hammers fall height) and place the gauge under one of the hammers of the Tapping Machine (pic. 3/4). (It is possible to use the gauge with general Tapping Machine noise generators, with a minimum height of 29/30 mm. For the Tapping Machines produced by Sources Line after 2014 the gauge needs a modification, realized after the customer’s request).

After having placed the G50 turn on the Tapping Machine, rotate the caster until eliminating the play of the hammers (tolerance 40 +/- 2 mm). Remove the G50 and observe the enumerated notches of the mobile head, checking the nonio for a more precise measure (pic. 5).

MAINTENANCE: sometimes it could be difficult to rotate the spiked caster due to the friction between the different parts. If this happens, unscrew manually the G50 handle and apply some oil in the hole, rotate repeatedly the caster and then screw the handle.