Tapping Machine – EOS

EOS looks like a small suitcase, it’s easily transportable and stowable.

Not only is our Tapping Machine entirely built with laser-bevelled aluminium, modelled by highly precise bending presses, but it is also provided with a solid and impeccable frame.

The current EOS Tapping Machine model has a minimum weight of 10.6 Kg.

When the battery is inside its specific space and the hammers bottom cover is applied, the Machine reaches a weight of 12.7 Kg.

The peculiarity that makes this Impact Noise Generator unique is the electromagnetic lifting system of the five hammers that guarantees an excellent precision of the fall timings, that no other system can reach, and it avoids the vibrations and the ground noise, things that are usually emanated by Tapping Machines with electromecanic automation.

An important upgrade, that makes the new EOS Impact Sound Generator even more competitive, is the replacement of two components. The heavy power supply transformer and the switch, used to select the grid potential difference, have been replaced by a state-of-the-art switching power supply that lets the system work with a potential difference between 100 V~ and 240 V~ ± 10 %, entailing a remarkable loss of weight, if compared to the preceding edition of our Tapping Machine.

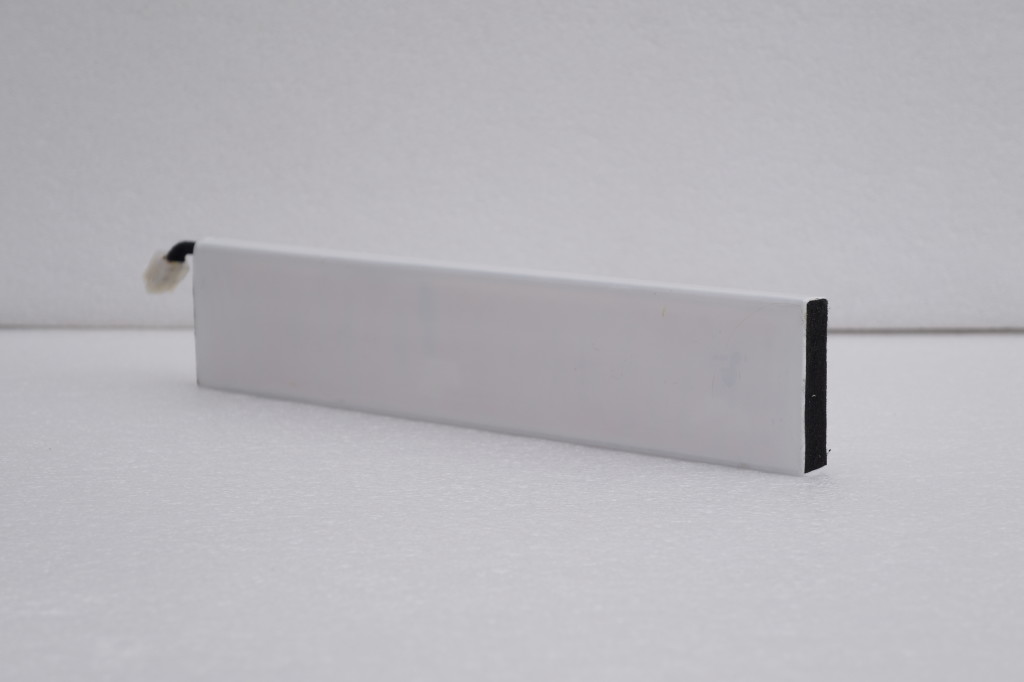

EOS has been provided with a new electronic management, checked by a microprocessor that marks the fall timings of the hammers with excellent precision and a higher productivity, with a power of 125 W and a battery duration of approximately one hour, if used in continuous work. The battery charge is expressed in percentage through a LCD battery indicator.

The new electronic board has been scrupulously created by Sources Line in order to adapt to the most advanced technology and to minimize the system malfunction risks. In case of malfunction, it has been specifically designed to reduce the costs of repairs and it presents simplified cabling connections and a simplified assembly system. EOS differs from EM50 in various ways. EOS does not have weld joints but rapid connectors, and its electronic parts are not soldered to the framework, but to specific modular clamps that can be easily disassembled and reassembled.

What we offer is a faster replacement of the damaged components that the customer can easily ship to the manufacturer, avoiding the shipping of the entire Tapping Machine. Rapid customer assistance and lower transport costs are our new watchwords.

The lightness of our EOS Impact Sound Generator reduces the possible damages caused by hauliers during the transportations and facilitates the construction sites relocations.

This instrument for the evaluation of spaces acoustic features has been projected and is completely built by Sources Line, situated in the low Po valley, in province of Modena.

The acoustic source EOS is an excellent tool that laboratories, universities, engineers and competent technicians should have among their professional equipment.

The kit that Sources Line usually gives to its customers is composed of: EOS Tapping Machine, Battery Pack (placed on the rear part of the machine, in its specific compartment), remote control to use the machine from distance, charging cable and padded shoulder transport bag. The factory can also supply, under request, a flight case, ideal for the air transports.

The electromagnetic system

What makes the EOS Sources Line impact sound generator different from the other Tapping Machines on the market?

Sources Line chooses the electromagnetic system.

The electromagnetic Tapping Machine does not have mechanical parts and uses the action of a magnetic field generated by five solenoids to raise the hammers, keeping them perfectly in the middle of the track on which they move.

The three fundamental advantages which differ our Tapping Machine electromagnetic system from the others are the following:

1. Precision and high impact repeatability

The electromagnetic noise generator Tapping Machine, thanks to an electric circuit that establishes the impact frequency (10 Hz +/- 0.001 %), guarantees high stability of the number of impacts, excluding further rebounds consecutive to the first and fundamental one.

This technology, that provides a “soft” grab of the hammers (without vibrations) and an adjustable and pre-calibrated motion-end, determines a constant fall of heights of 40 mm, independently from the typology and the hardness of the tested floors.

2. It does not need any maintenance

Not having geared motor and mechanical parts in movement, such as belts and gears, the EM50 Tapping Machine has really low interferences generated by friction and vibration, causing an almost total absence of wear.

3. Measurements reliability

During the fall and raising phase, thanks to the “flotation” of the hammers provoked by the electromagnetic field in the track, the hammers have a reduced friction in every moment of their movement. In this way vibrations are not transmitted to the frame and to the floor; they could provoke interferences and (bottom) noise and therefore alter the tests values.